مقایسه Gyratory Crusher Vs Jaw Crusher M

The Features and Differences between Jaw Crusher and Gyratory Crusher ...

2021年9月2日 1. Jaw Crusher 2. Gyratory Crusher 3. Compare of J aw Crusher and Gyratory Crusher To Wrap Up There are many types of crushers in mining, mainly jaw crushers, gyratory crushers, impact crushers, cone crushers, hammer crushers and roller

Read More

Gyratory VS Jaw Crushers: Advantages

2016年2月28日 The jaw crusher will handle sticky,’or dirty feed better than the gyratory, there being no diaphragm below the crushing chamber on

Read More

Compare Gyratory Crusher vs Jaw Crusher - 911

2015年7月18日 Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW

Read More

Jaw Crusher VS Gyratory Crusher - JXSCMACHINE

2019年4月20日 Compared with the jaw crusher, the feeding size of the rotary crusher is larger, the discharging size is smaller and more uniform, and the content of needle-like particles in the discharging is less than

Read More

Hard Rock Applications: Gyratory vs Jaw Crusher Mellott

2023年8月14日 Gyratory vs Jaw Crusher: Factors To Consider When Making The Choice. Several factors need to be considered when choosing between a gyratory and jaw

Read More

Gyratory Crusher - an overview ScienceDirect Topics

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 1.5 m (for the largest equipment). – This crusher can handle products with a Mohs hardness that is not

Read More

Jaw Crusher VS Gyratory Crusher - baichy

2023年7月8日 Both the gyratory crusher and the jaw crusher are used for primary crushing equipment in sand and gravel aggregates production plant. They are similar in function

Read More

Selecting the Right Crushing Equipment Agg-Net

2015年10月28日 Attrition crushers – which use both impact and grinding to shear the material. Jaw crushers, cone crushers, gyratory crushers and roll crushers all operate on the compression principle. Impact crushers utilize

Read More

Minerals Free Full-Text Torque Analysis of a Gyratory Crusher

2021年8月13日 A Metso 60-110 gyratory crusher has been modeled by using the Discrete Element Method with the software Rocky DEM. The diverse comparisons studied

Read More

Compare Gyratory Crusher vs Jaw Crusher - 911

2015年7月18日 Gyratory Crusher Jaw Crusher Compared. There is another comparison that should be taken into consideration, that is the amount of space that each takes. The Jaw crusher is the smaller of the

Read More

Jaw Crusher Explained - saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate

Read More

How it Works: Crushers, Grinding Mills and

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

Read More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a ...

Read More

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Largest jaw crusher is 1600 x 2514 mm with motor ratings of 250-300 kW. Metso crushers (C200 series) are 1600 x 2514 mm with motors rated at 400 kW. ... Gyratory Crusher History Gyratory Crusher History [image: (135-5-15)] Gyratory Crusher Dimensions. Breaking head (mantle) is fixed to a central spindle which is suspended from a spider ...

Read More

Unveiling the Advantages and Applications of Gyratory Cone

2023年2月28日 Uniform particle size distribution: The crushing chamber of a gyratory cone crusher is designed in such a way that the particles are subjected to a uniform force throughout the crushing process. This ensures a more uniform particle size distribution in the final product. Lower operating costs: Gyratory cone crushers have a lower operating cost ...

Read More

Type of crushers and their difference - JXSC Mining

2019年12月10日 gyratory crusher working principle animation. image credit by 911 Metallurgist. Similar to a jaw crusher, the gyratory crusher pulverizers the stones by placing them between two manganese steel plates and going straight down. It does not rotate, rather it is powered by electricity. Gyratory crushers are used in mine or ore processing

Read More

Jaw Crusher VS Impact Crusher (A Comparison from 7

2020年2月28日 1. Application. 1. Jaw crushers are mainly used as primary crushers, it can crush hard material, such as granite, basalt. 2. Impact crusher is usually used as a medium-fine hardness crusher, such as limestone, concrete, it has good crushing efficiency of some brittle material. It mainly crushes the small material discharge from the jaw crusher.

Read More

Mathematics Free Full-Text Mathematical Modeling and

2023年5月17日 A differential equation was derived. As a result of its solution, the rational shape of the working chamber cheek of the single-roll gyratory crusher was established, representing a logarithmic spiral arc. Analytical expressions were derived to determine the rational rotation speed and productivity of the crusher under consideration.

Read More

GC gyratory crusher - nmsindustries

The GC series gyratory crusher is an advanced crusher at present, suitable for the primary crushing of various rocks and ores, features as follows: large capacity, high crushing efficiency, larger reduction ratio, consistent product size, lower consumption, etc, fit for the application of larger capacity. When OSS at 150mm, the pass through ...

Read More

Gyratory Crusher vs. Cone Crusher: What's the

2023年2月23日 In terms of design and construction, gyratory crushers and cone crushers have distinct differences. A gyratory crusher has a mantle that rotates within a concave bowl, while a cone crusher has a mantle

Read More

THE EFFECT OF LINER WEAR ON GYRATORY

2011年6月21日 The same approach was used for investigating the influence of liner wear on crushing performance for a primary gyratory crusher [71]. Fig. 6 shows an example of flow and breakage prediction in

Read More

2. GYRATORY CRUSHERS - 911 Metallurgist

2017年4月19日 The gyratory crusher, whether used as a primary or secondary. is essentially a gravity-type machine. Material flows vertically from top to bottom. It receives a large coarse feed, usually run-of-mine, and its product normally requires additional crushing before produc- ing the final product. The gyratory crusher is a pressure crushing device

Read More

5 Common Questions about Jaw Crushers Answered

2019年5月30日 The space at the bottom of the V-aligned jaw plates is the output gap that dictates the size of the crushed product from the jaw crusher. The rock remains in the jaws until it is small enough to ...

Read More

Jaw Crusher - an overview ScienceDirect Topics

Applying the crushing force by rolling the nut breaks flats and gives a product that is more “cubic” than the jaw crusher. – The largest-scale equipment can treat a flow with the magnitude of 4,000 tonne.h − 1. – With a production rate and flow that are equal, the power consumed by a gyratory crusher is similar to a jaw crusher.

Read More

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023年5月27日 The overall structure of the machine. From the perspective of the overall structure, the cone crusher is 1.7-2 times heavier and 2-3 times higher than the jaw crusher with the same feeding opening size. A Larger machine means

Read More

Gyratory Crushers - 911 Metallurgist

2016年2月17日 Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501). The crushing head is carried on a short solid main shaft (515 ...

Read More

Minerals Free Full-Text Torque Analysis of a Gyratory Crusher

2021年8月13日 Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect. To optimize the design and to improve the availability of gyratory crushers, it is necessary to calculate their power and torque

Read More

- شركات التعدين في ناميبيا وتجهيزات

- الحجر الصلب الجرانيت الربيع مخروط محطم

- شن و ماسه ساخت و ساز شن و ماسه عمودی ضربه شافت ضربه

- معادن سنگ صابون در پاکستان

- يريد لشراء الفك كسارة الصخور

- السعر المورد محطم

- تصویر خط تولید کوارتز

- محطة كسارة المحمول خط كسارة

- الفك صغير صخرة محطم بيع

- الفك محطم الاحتراق

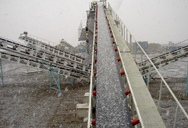

- الجلود الحزام الناقل

- عن التعدين على نطاق صغير

- مصنع طحن باريت تشاينا

- به کره دستگاه pictures3 قطعات یدکی

- فروش کارخانه پرکننده